Does your warehouse have a traffic plan? Forklifts and pedestrians often cross paths in warehouses and other industrial facilities. Just like on any walkway, it’s vital to have safeguards in place to manage the movement of people, vehicles and machinery. Accidents can happen between forklifts and people when walkway safety standards are neglected.

Warehouses are busy environments with lots of activity, and they can be hazardous places to work if proper safety measures are not taken. One of the key areas where safety should be a top priority is warehouse walkways. Below are ways to create a safe warehouse walkway.

1. Plan the Walkway Layout

The first and one of the most vital steps in creating a safe warehouse walkway is to plan the layout. Make sure to consider the traffic flow, the equipment that will be used in the area, and the space available. Ensure that the walkway is wide enough to accommodate foot traffic and any equipment or vehicle that may need to pass through.

2. Use Proper Floor Markings

Proper markings are essential for creating a safe walkway. Use bright and visible floor marking tapes to mark the walkway on the floor, and make sure the markings are consistent and clear. Use arrows to indicate the direction of traffic flow, and mark off areas that are off-limits to foot traffic.

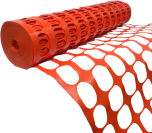

3. Install Safety Barriers

Safety barriers are a key method to preventing foot traffic from entering hazardous areas. Use guardrails, fencing, and other barriers to keep pedestrians safe. Barriers should be strong enough to withstand impact from equipment and be high enough to prevent people from climbing over them.

4. Ensure the Right PPE is Always Used

Wearing high visibility personal protective equipment, including safety vests, and high vis clothing, is another valuable tip to ensure the safety of workers in the warehouse.

5. Keep the Walkway Clear

Warehouse walkways should always be kept clear of obstacles and clutter. Make sure that equipment and materials are stored in designated areas, and that they do not block any walkways. This will help prevent trips and falls, which are common hazards in a busy warehouse environment.

6. Identify and Mark Hazardous Zones Clearly

Safety signages and stickers are the most cost-effective and functional way of keeping your warehouse organised and safe from hazardous situations. Putting proper labels on racks, equipment, and materials clearly can help workers prevent serious injuries. Additionally, it's also important that emergency exits and the safest routes to them are clearly marked

7. Provide Training

Nothing beats attentiveness and awareness when it comes to preventing accidents. Make sure everyone in the facility is educated and trained about your company’s safety codes. Both forklift drivers and pedestrians need to play by the same set of rules. Employers should conduct safety training sessions and post safety signs outlining safety practices.

8. Maintain Vehicle Safety

Whether you work with forklifts or lift trucks, vehicle safety is crucial to preventing crush injuries. This can be done by ensuring workers are provided proper practical training about maintaining speed limits, avoiding reversing whenever possible and being aware of blind spots. It's also vital to enforce a zero-tolerance policy for reckless driving.

Creating safe warehouse walkways is essential for preventing accidents and ensuring the safety of all workers. By following these steps, you can create a safe and efficient traffic plan that will help keep your warehouse running smoothly.

At Southland, we offer a wide range of products to maintain a safe warehouse walkway including floor marking tapes, safety barriers and PPE such as hi-vis vests, and more.