There are many chemicals in common use that can cause serious to personal health and the environment. While a chemical may be fine on its own, if you mix two chemicals, each with known properties, can cause unexpected effects when they are put together.

The new EN ISO 374 standard is designed to ensure consistency in testing chemical resistant gloves and helps users and safety professionals as they determine their chemical protection needs.

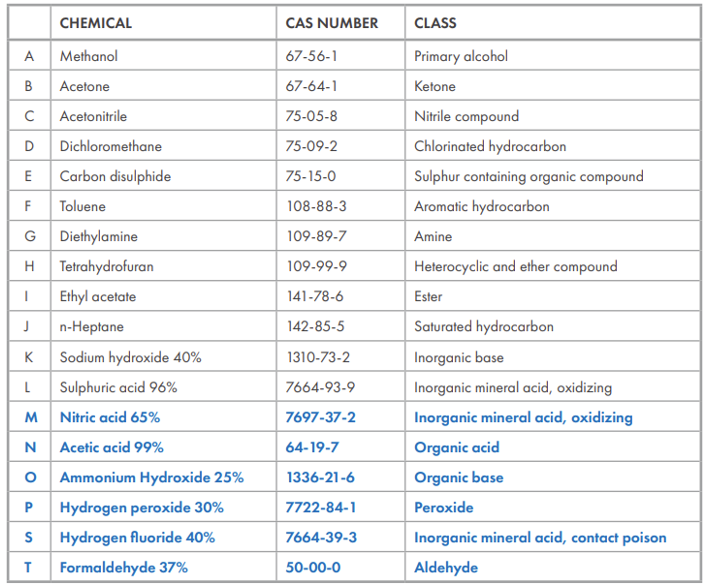

This standard gives directives on how to test degradation and permeation for 18 chemicals but doesn’t reflect the actual duration of protection in the workplace and the differences between mixtures and pure chemicals.

The EN ISO 374 standard stipulates the requirements of manufacturers to test chemical gloves for Permeation, Penetration and Degradation.

Penetration

Penetration is the movement of a chemical and/or micro-organism through pinholes or other imperfections in a protective glove material at a non-molecular level.

Permeation

The rubber and plastic films in safety gloves are the barriers to chemicals. Therefore, it is necessary to measure breakthrough times, or the time taken for the hazardous liquid to encounter the skin. Every chemical tested is classified regarding breakthrough time performance levels 0 to 6.

Degradation

There are times that chemical resistant gloves can act as sponges, soaking up the liquids and holding them against the skin. This process degrades the safety glove. Degradation is the change in one or more physical characteristics of the safety glove caused by contact with a chemical. Indications of degradation include flaking, swelling, disintegration, embrittlement, colour change, dimensional change, appearance, hardening, softening, etc.

EN ISO 374-1:2016 defines a list of 18 chemicals (6 more than EN 374:2003):

Marking of Chemical Resistant Gloves

Type A - Safety gloves with permeation resistance of at least 30 minutes each for at least 6 test chemicals.

Type B – Safety gloves with permeation resistance of at least 30 minutes each for at least 3 test chemicals.

Type C – Safety gloves with permeation resistance of at least 10 minutes for at least 1 test chemical.

Regarding the new classification, experts already agree that the 3 new type classes are unlikely to generate new differentiations between the product categories already on the market. Most chemical resistant gloves can be assigned to type class A; only thin disposable protective gloves will be assigned to types B and C. The practical use for the user is debatable.

If you have any further questions or would like to discuss your specific safety requirements and how the changes to the EN 374 standard could affect you, you may contact us at 1800 77 22 91 or webstore@southland.com.au. You may also browse our wide range of chemical resistant gloves and other personal protective equipment at https://www.southland.com.au/