Abrasives are essential tools in the construction industry, serving a wide range of purposes such as sanding, cutting, and grinding. Whether you're a seasoned professional or a DIY enthusiast, understanding the role of abrasives in construction is crucial for achieving high-quality results. In this blog, we'll delve into the world of abrasives, exploring their various uses and importance in construction.

What are Abrasives?

Abrasives are materials used for grinding, cutting, or smoothing surfaces by wearing away unwanted material. In construction, the following types of abrasives are commonly employed:

Types of Abrasives

1. Sandpaper - Sandpaper is a versatile abrasive that comes in various grit sizes, typically measured in numbers referred to as grit, such as 40, 60, 80, and 120 grit. Coarser grits are used for heavy material removal, while finer grits are ideal for smoothing surfaces. Sandpaper is crucial for preparing surfaces before painting, staining, or finishing, and for removing imperfections on walls, wood, and other construction materials.

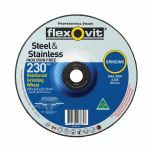

2. Grinding Wheels - Grinding wheels are essential tools for smoothing, shaping, or sharpening metal, concrete, and masonry surfaces. These wheels are made from abrasive particles bonded together, and they come in various types, including aluminum oxide, silicon carbide, and diamond. Each type is suited to different applications, making them indispensable in construction work.

Grinding wheels are also used to level uneven surfaces, remove surface imperfections, and create a polished finish. In the case of concrete floors, grinding is vital for preparing surfaces for coatings and achieving a professional, high-gloss appearance.

3. Cutting Discs - Cutting discs, often made of abrasive materials like aluminum oxide or silicon carbide, are used for slicing through materials such as metal, concrete, and masonry. They are commonly employed in construction to cut reinforcing bars, pipes, and other structural components to the desired length.

Safety Considerations when Using Abrasives

Working with abrasives in construction demands strict adherence to safety protocols to protect both professionals and the quality of the final result:

1. Personal Protective Equipment: Always wear appropriate PPE, including safety glasses, dust masks, hearing protection, and safety gloves when working with abrasives. PPE helps safeguard your eyes, respiratory system, hearing, and hands from potential hazards.

2. Work in a well-ventilated area: Adequate ventilation is crucial, especially when working with abrasive materials that produce dust or fumes. It helps maintain air quality and reduces the risk of respiratory issues.

3. Follow manufacturer guidelines: Always adhere to the manufacturer's instructions regarding abrasive materials, tools, and equipment to ensure safety and efficiency.

Abrasives are indispensable tools in the construction industry, serving various purposes such as sanding, cutting, and grinding. Understanding the types of abrasives and their applications is vital for construction professionals to achieve high-quality results and ensure the safety of their projects. By using abrasives wisely and following safety guidelines, construction experts can create structures with smooth surfaces and precise dimensions, ultimately enhancing the quality and longevity of their work.

Whether you're finishing a wooden surface, cutting through concrete, or grinding metal, Southland has the right type of abrasives for you. Browse our range online today!